- 您现在的位置:买卖IC网 > Sheet目录337 > LT3519EMS-2#PBF (Linear Technology)IC LED DRVR HP CONST CURR 16MSOP

LT3519/LT3519-1/LT3519-2

APPLICATIONS INFORMATION

L ( μH ) = BUCK

D ? ( V IN – V LED ) ? μH ? A ? MHz ?

f OSC (MHz) ? 0.15A ?

V

?

D BUCK = LED

L ( ) =

D BOOST ? V IN ? μH ? A ? MHz ?

( V LED – V IN )

V LED

Inductor Selection

The inductor used with the LT3519/LT3519-1/LT3519-2

should have a saturation current rating of 1A or greater.

For buck mode LED drivers, the inductor value should be

chosen to give a ripple current 150mA or more. In the

buck mode, the inductor value can be estimated using

the formula:

? ?

V

V IN

V LED is the voltage across the LED string, V IN is the input

voltage to the converter, and f OSC is the switching frequency.

In the boost con?guration, the inductor can be estimated

using the formula:

μH ? ?

f OSC (MHz) ? 0.15A ? V ?

D BOOST =

ESL and have an adequate ripple current rating. A 2.2μF

ceramic type capacitor is usually suf?cient for LT3519

(400kHz version). A capacitor of proportionately less

value for LT3519-1/LT3519-2 (higher frequency version)

can be used.

Output Capacitor Selection

The selection of output capacitor depends on the load

and converter con?guration, i.e., step-up or step-down

and the operating frequency. For LED applications, the

equivalent resistance of the LED is typically low, and the

output ?lter capacitor should be sized to attenuate the

current ripple.

To achieve the same LED ripple current, the required ?lter

capacitor value is larger in the boost and buck-boost mode

applications than that in the buck mode applications. Lower

operating frequencies will require proportionately higher

capacitor values. For LED buck mode applications, a 1μF

ceramic capacitor is usually suf?cient. For the LED boost

and buck-boost mode applications, a 2.2μF ceramic ca-

pacitor is usually suf?cient. Very high performance PWM

dimming applications may require a larger capacitor value

to support the LED voltage during PWM transitions.

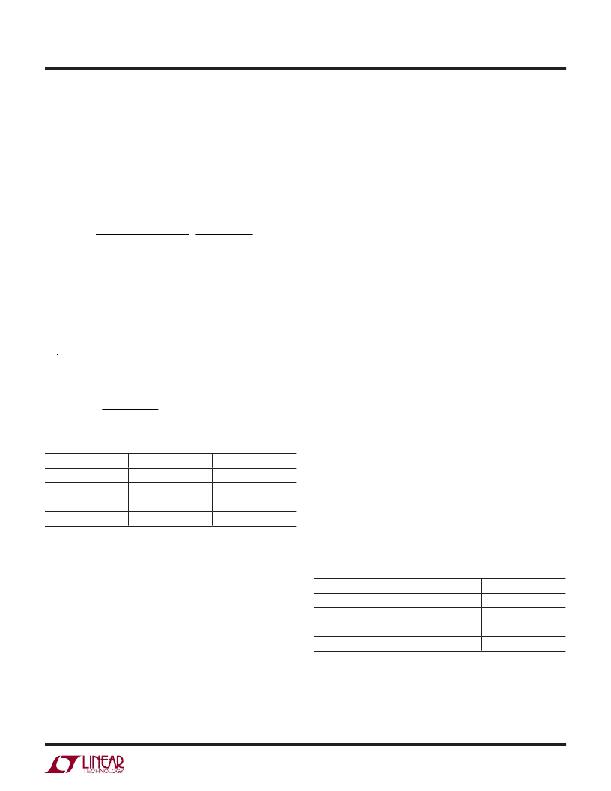

Table 1. Recommended Inductor Vendors

VENDOR PHONE

WEB

Use only ceramic capacitors with X7R, X5R or better dielec-

tric as they are best for temperature and DC bias stability

Sumida

Toko

Cooper

Vishay

(408)321-9660

(408)432-8281

(561)998-4100

(402)563-6866

www.sumida.com

www.toko.com

www.cooperet.com

www.vishay.com

of the capacitor value. All ceramic capacitors exhibit loss

of capacitance value with increasing DC voltage bias, so

it may be necessary to choose a higher value capacitor

to get the required capacitance at the operation voltage.

Input Capacitor Selection

For proper operation, it is necessary to place a bypass

capacitor to GND close to the V IN pin of the LT3519/

LT3519-1/LT3519-2. A 1μF or greater capacitor with low

Always check that the voltage rating of the capacitor is

suf?cient.

Table 2. Recommended Ceramic Capacitor Vendors

VENDOR PHONE WEB

ESR should be used. A ceramic capacitor is usually the

best choice.

In the buck mode con?guration, the capacitor at the input

to the power converter has large pulsed currents. For

TDK

Kemet

Murata

Taiyo Yuden

(516)535-2600

(408)986-0424

(814)237-1431

(408)573-4150

www.tdk.com

www.kemet.com

www.murata.com

www.t-yuden.com

best reliability, this capacitor should have low ESR and

3519fa

11

发布紧急采购,3分钟左右您将得到回复。

相关PDF资料

LT3590ESC8#TRMPBF

IC LED DRVR WHITE BCKLGT SC-70-8

LT3591EDDB#TRMPBF

IC LED DRIVER WHITE BCKLGT 8-DFN

LT3593ES6#TRMPBF

IC LED DRIVR WHITE BCKLGT TSOT-6

LT3595AEUHH#TRPBF

IC LED DRIVR WHITE BCKLGT 56-QFN

LT3595EUHH#TRPBF

IC LED DRIVR WHITE BCKLGT 56-QFN

LT3596EUHG#PBF

IC LED DVR 300MA ADJ 52-VQFN

LT3597EUHG#PBF

IC LED DRIVER TRPL STP DWN 52QFN

LT3598IUF#PBF

IC LED DRIVR WHITE BCKLGT 24-QFN

相关代理商/技术参数

LT3519EMS-2#PBF

制造商:Linear Technology 功能描述:IC LED DRIVER BOOST MSOP-16

LT3519EMS-2#TRPBF

功能描述:IC LED DRV HP CONST CURR 16MSOP RoHS:是 类别:集成电路 (IC) >> PMIC - LED 驱动器 系列:- 标准包装:6,000 系列:- 恒定电流:- 恒定电压:- 拓扑:开路漏极,PWM 输出数:4 内部驱动器:是 类型 - 主要:LED 闪烁器 类型 - 次要:- 频率:400kHz 电源电压:2.3 V ~ 5.5 V 输出电压:- 安装类型:表面贴装 封装/外壳:8-VFDFN 裸露焊盘 供应商设备封装:8-HVSON 包装:带卷 (TR) 工作温度:-40°C ~ 85°C 其它名称:935286881118PCA9553TK/02-TPCA9553TK/02-T-ND

LT3519EMSPBF

制造商:LINER 制造商全称:Linear Technology 功能描述:LED Driver with Integrated Schottky Diode

LT3519EMSTRPBF

制造商:LINER 制造商全称:Linear Technology 功能描述:LED Driver with Integrated Schottky Diode

LT3519IMS

制造商:LINER 制造商全称:Linear Technology 功能描述:LED Driver with Integrated Schottky Diode

LT3519IMS#PBF

功能描述:IC LED DRV HP CONST CURR 16MSOP RoHS:是 类别:集成电路 (IC) >> PMIC - LED 驱动器 系列:- 标准包装:6,000 系列:- 恒定电流:- 恒定电压:- 拓扑:开路漏极,PWM 输出数:4 内部驱动器:是 类型 - 主要:LED 闪烁器 类型 - 次要:- 频率:400kHz 电源电压:2.3 V ~ 5.5 V 输出电压:- 安装类型:表面贴装 封装/外壳:8-VFDFN 裸露焊盘 供应商设备封装:8-HVSON 包装:带卷 (TR) 工作温度:-40°C ~ 85°C 其它名称:935286881118PCA9553TK/02-TPCA9553TK/02-T-ND

LT3519IMS#TRPBF

功能描述:IC LED DRV HP CONST CURR 16MSOP RoHS:是 类别:集成电路 (IC) >> PMIC - LED 驱动器 系列:- 标准包装:6,000 系列:- 恒定电流:- 恒定电压:- 拓扑:开路漏极,PWM 输出数:4 内部驱动器:是 类型 - 主要:LED 闪烁器 类型 - 次要:- 频率:400kHz 电源电压:2.3 V ~ 5.5 V 输出电压:- 安装类型:表面贴装 封装/外壳:8-VFDFN 裸露焊盘 供应商设备封装:8-HVSON 包装:带卷 (TR) 工作温度:-40°C ~ 85°C 其它名称:935286881118PCA9553TK/02-TPCA9553TK/02-T-ND

LT3519IMS-1#PBF

功能描述:IC LED DRV HP CONST CURR 16MSOP RoHS:是 类别:集成电路 (IC) >> PMIC - LED 驱动器 系列:- 标准包装:6,000 系列:- 恒定电流:- 恒定电压:- 拓扑:开路漏极,PWM 输出数:4 内部驱动器:是 类型 - 主要:LED 闪烁器 类型 - 次要:- 频率:400kHz 电源电压:2.3 V ~ 5.5 V 输出电压:- 安装类型:表面贴装 封装/外壳:8-VFDFN 裸露焊盘 供应商设备封装:8-HVSON 包装:带卷 (TR) 工作温度:-40°C ~ 85°C 其它名称:935286881118PCA9553TK/02-TPCA9553TK/02-T-ND